Fiber laser cutting machine application

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, grain machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal external processing, kitchen utensils processing and other manufacturing and processing industries.

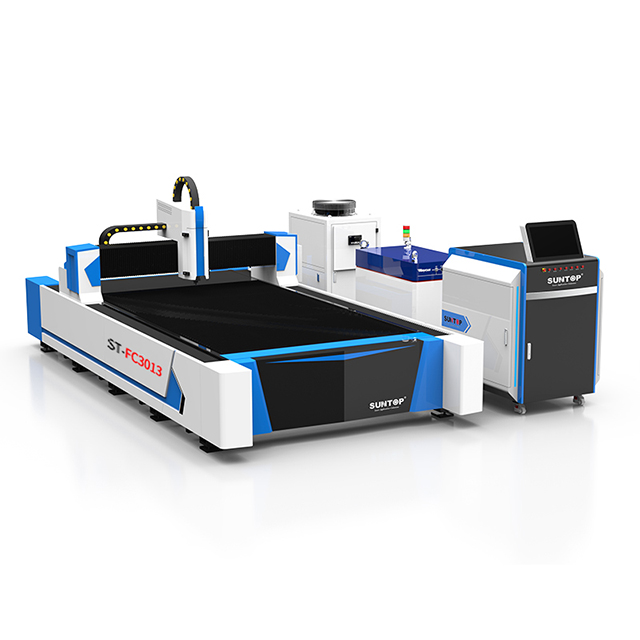

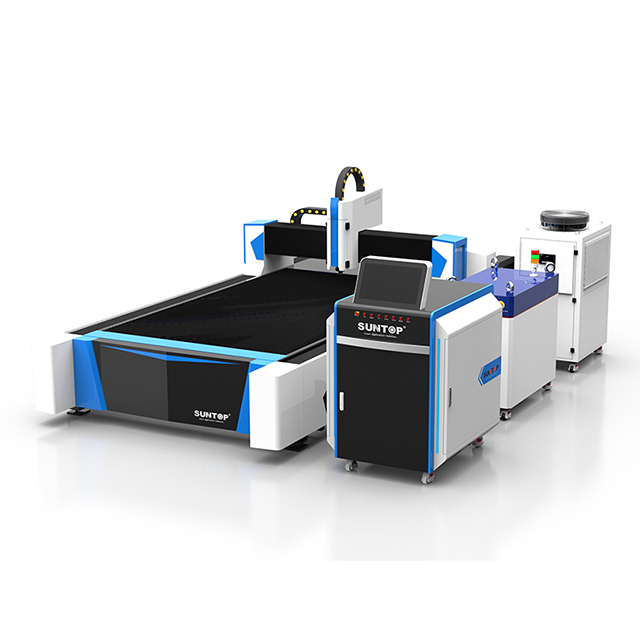

Fiber laser cutting machine components

1. Fiber laser

The laser is the core "power source" of the fiber laser cutting machine, and it is also an expensive component in the fiber laser cutting machine. There are fiber lasers such as IPG and RAYCUS.

2. Motor

The motor of the fiber laser cutting machine is the core component of the motion system. The performance of the motor directly affects the effect of product processing and production efficiency. Commonly used motors are stepper motors and servo motors. Configure according to the industry type and product type of the cutting object.

A. Stepping motor:

Fast start-up, responsive, suitable for less demanding cutting. The price is lower. There are many brands of stepper motors with different performances.

B. Servo motor:

High motion, stable motion, high load, stable performance, smooth edges of processed products, fast cutting speed, high price, suitable for industries and products with high cutting requirements.

3. Fiber laser cutting head

The fiber laser cutting head is a laser output device consisting of a nozzle, a focusing lens and a focus tracking system. The cutting head of the fiber laser cutting machine will walk according to the set cutting trajectory, but the height of the laser cutting head needs to be adjusted and controlled according to different materials, different thicknesses, and different cutting methods.

4. Laser lens

Laser lenses are mostly used in the entire fiber laser cutting equipment. Many optical devices contain laser lenses. Different lenses have different functions, such as total reflection lens, semi-reflection lens, focusing lens, etc. The quality of the lens directly affects the output power of the laser, and also affects the performance of the entire fiber laser machine.

5. Host workbench

The bed, beam, table, and Z-axis system of the fiber laser cutting machine are collectively referred to as the host. When cutting, the fiber laser cutting machine first puts the workpiece on the bed, and then uses the servo motor to drive the beam to control the movement of the Z axis. Users can adjust the parameters according to their needs.

6. Rack

Fiber laser cutting machines have very high requirements for machine stability. At present, the mainstream shelves on the market are gantry type, cantilever type, beam type, etc. Different shelves have different functions. For example, the beam frame is mainly used for material cutting of large manufacturers. There are also domain-specific models, such as 3D fiber laser cutting, which is mainly used in the automotive industry.

7. Chiller

The chiller is the cooling device of the fiber laser cutting machine, which can quickly and efficiently cool down lasers, spindles and other equipment. The current chillers are equipped with input and output control device switches, advanced cooling water flow, high and low temperature alarms and other functions, and the performance is more stable.

8. CNC fiber laser cutting system

The control system is the leading operating system of the fiber laser cutting machine, which mainly controls the movement of the machine tool to realize the X, Y, and Z axes, and also controls the output power of the laser. Its quality determines the stability of the fiber laser cutting machine's operating performance. Through software control, the cutting effect can be improved.

9. Air supply system

The air supply system of fiber laser cutting machine mainly includes air source, filter device and pipeline. Among them, there are two types of air sources: bottled air and compressed air. The auxiliary gas blows away the slag when cutting metal, plays a role in supporting combustion, and also has a certain protective effect on the cutting head.

10. Other parts

A. Air-cooled dryer, filter: used to provide clean and dry air to the laser generator and beam path to keep the path and reflector working normally.

B. Ventilation and dust collector: suction and filter the smoke and dust generated during the processing, so that the exhaust gas emission can meet the environmental protection standard.

C. Slagging machine: remove the leftover materials and waste generated during the processing.

D. Stable power supply: The power supply is connected between the laser, CNC machine tool and power supply system. It mainly plays the role of preventing external power grid interference.

Fiber laser cutting machine function

1. Automatic follow-up: The metal fiber laser cutting machine automatically follows during operation.

2. Automatic sorting: programming, nesting and nesting of parts that need to be cut.

3. Automatic compensation: In order to compensate for the size difference caused by the loss of the cutting seam, the CNC metal plate fiber laser cutting machine automatically compensates the material to ensure the product accuracy.

4. Automatic edge finding: Perceive the inclination angle and origin of the plate, and cut at the angle and position suitable for the plate to avoid waste of raw materials.

5. Breakpoint memory: When the power is cut off, the system records the pause state of the machine, and after the machine fiber laser cutting restarts, it can continue to work on the original basis.

6. Automatic leapfrogging: parabolic movement is adopted in the empty stroke, which reduces the time for lifting the cutter head and improves cutting efficiency. It is often referred to as "leapfrogging".

7. Automatic frame movement: Before blanking, confirm the processing range through software settings to ensure that the required blanking does not shift.

Automatic lead adding: automatically set the lead position to prevent burns on the head and tail of the workpiece.

8. Co-edge cutting: The fiber metal plate laser cutting machine arranges the long side parts according to certain rules in the way of long side to long side, and only cuts the common side part of the outer side to generate the outline of these parts when cutting commands. Save time, save material.

9. Can read DXF/AI/PLT format files and international standard G code

10. Automatic micro-link: During the operation of the stainless steel fiber laser cutting machine, the parts are not separated from the plate, ensuring that the parts are not deformed and the laser head is safe during rapid movement.