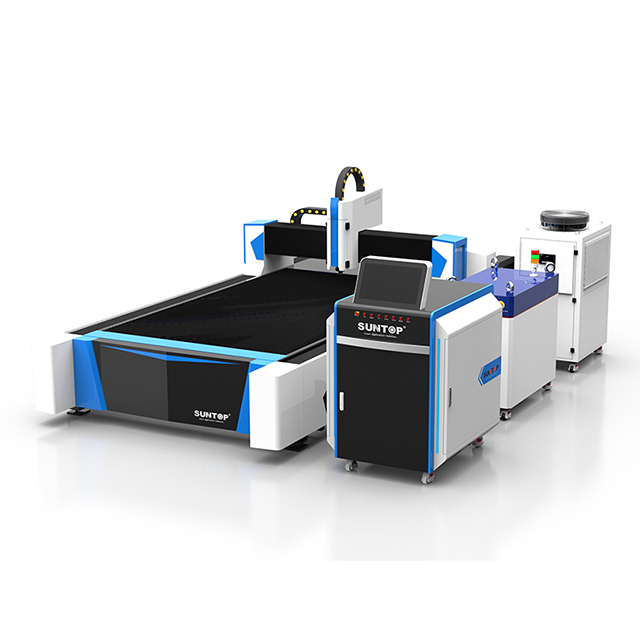

Fiber laser cut aluminum design concept

The laser of the fiber laser can be transmitted through the optical fiber, which is convenient to connect with the motion platform and realize flexible processing, which greatly simplifies the system design of the traditional laser cutting machine, improves the stability of the system, reduces the amount of maintenance, and is really suitable for the field of industrial processing. Applications. It has better cutting quality, lower system cost, longer service life, lower maintenance cost, and lower power consumption. The designed body can be more ergonomic and easy to operate.

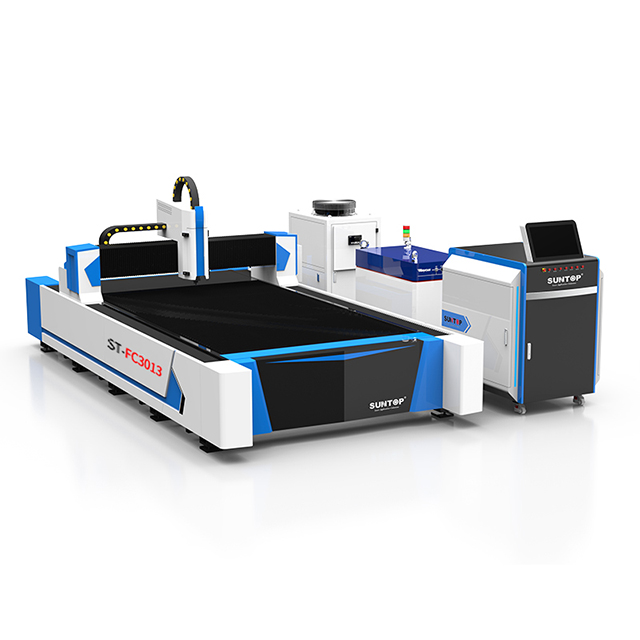

Fiber laser cut aluminum quantity

1. High cutting precision: the positioning accuracy of the laser cutting machine is 0.05 mm, and the repeat positioning accuracy is 0.03 mm.

2. The laser cutting machine has a narrow slit: the laser beam is focused into a small light spot, so that the focal point reaches a high power density, and the material is quickly heated to the degree of gasification, and evaporates to form holes. As the beam moves linearly relative to the material, the holes are continuously formed into a very narrow slit, and the slit width is generally 0.10-0.20mm.

3. The cutting surface of the laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the incision is generally controlled within Ra6.5.

4. The laser cutting machine is fast: the cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than wire cutting.

5. The cutting quality of the laser cutting machine is good: non-contact cutting, the cutting edge is slightly affected by heat, basically no thermal deformation of the workpiece, completely avoiding the collapse of the material during punching and shearing, and the cutting seam generally does not require secondary processing.

6. No damage to the workpiece: the laser cutting head will not touch the surface of the material to ensure that the workpiece will not be scratched.

7. Not affected by the shape of the workpiece: laser processing has good flexibility, can process any graphics, and can cut pipes and other special-shaped materials.

8. The laser cutting machine can cut and process a variety of materials: such as stainless steel, carbon steel, aluminum, brass, etc.

9. Saving mold investment: laser processing does not require molds, no mold consumption, no need to repair molds, saves time for mold replacement, thereby saving processing costs and reducing production costs, especially suitable for processing large-scale products.

10. Material saving: Using computer programming, products of different shapes can be cut to maximize the utilization rate of materials.

11. Improve the speed of sample delivery: After the product drawing is formed, laser processing can be carried out immediately, and the new product can be obtained in the shortest time.

12. Safety and environmental protection: Laser processing has less waste, low noise, clean, safe and pollution-free, which greatly improves the working environment.

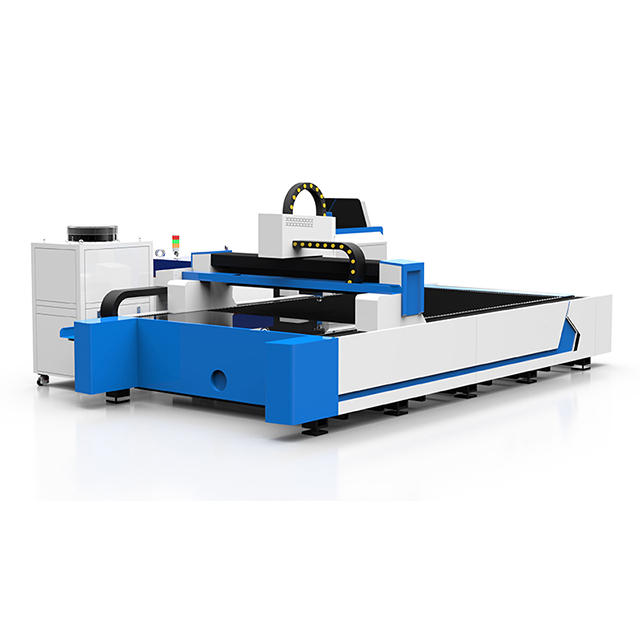

Laser cutting aluminum characteristics

1.Fine cutting slit: The cutting slit of laser cut aluminum is generally 0.1-0.2mm

2. Smooth cutting surface: the cutting surface of laser-cut aluminum is burr-free and slag-free

3. Small thermal deformation: laser processing of laser cutting slit fine, fast, concentrated energy, so the heat transferred to the cut material is small, causing very small material deformation

4. Material saving: laser processing using computer programming, laser equipment can be different shapes of aluminum processing parts for material sets of cutting, improve the material utilization rate of aluminum, saving a lot of material costs

5. How thick aluminum can be cut mainly depends on the power of the laser generator, generally 6000W thickest can be cut to 16mm, 4500W can be cut to 12mm

Laser cutting aluminum precautions

1. need to pay attention to the laser speed when cutting aluminum, aluminum itself is not resistant to high temperature, once the cutting dwell time is not appropriate will produce burrs. Through the cutting focus, speed, output power, air pressure and other parameters of the adjustment, you can better cut aluminum.

2. Select the appropriate auxiliary gas, because of the special color of aluminum and to protect the uniform color of the cut products, nitrogen can well prevent oxidation and retain the characteristics of the material itself, the use of nitrogen is a better choice.

3. Use special anti-reflective material cutting head, which can effectively reduce the reflection damage to the lens.